|

Special Effects & Services provide complete design services for control system design from the concept through to the final commissioning stage for fully automated pre-cast concrete production plants. |

|

Services |

|

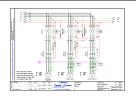

Autocad LT utilized to produce power distribution (3ph), lower voltage generation (110Vac, 24Vdc etc), emergency stop & safety circuit overviews, PLC network layouts, PLC input / output schematics. |

|

Electrical Schematic Circuit Design |

|

Autocad LT utilized to produce panel component layouts, control panel labels. EXCEL utilized for production of parts schedules & costings. |

|

Panel Layout & Controls Design |

|

Programming using the CX-One suite of programs (or alternatively Syswin for legacy applications) for most of the OMRON PLC’s including C20, C**K, C200H, C200HS, C200Hα, CQM, CS1, CPM1, CPM2, CJ1, CJ2 etc. digital & analogue i/o, counters, motion control etc. with i/o count from 20 through to 1000+ (a multiple C200Hα system with controller link networking). Previous experience with other PLC’s to a similar i/o count level including: ALLEN BRADLEY, MITSUBISHI, SIEMENS S7, TELEMECHANIQUE PL7. |

|

For more information about these services: |

|

E-mail: info@SEandS.co.uk |

|

P.L.C. Programming |

|

Experience producing full operator interfaces often with 100+ diagrammatic & operator input screens. Telemechanique Magellis, Omron NT HMI screens; Siemens Factory Link, Wonderware Intouch SCADA systems. |

|

H.M.I. / SCADA Programming |

|

Site Installation, Test & Commissioning |

|

Panel Refurbishment & PLC Upgrades

|

|

Operator & Technical Manual Construction |

|

Small Panel Construction |

|

Site Fault Finding & Rectification |

|

© Special Effects & Services 2011 |